Optimize data governance in the oil and gas sector with SAP MDG, ensuring accuracy, compliance, and streamlined operations.

Oil & Gas industry is one of the largest asset-intensive industries in the world. The industry is characterized by heavy investments, complex organizations, tremendous technical challenges, political and work-related risks.

Also, it is witnessed by the deployment of niche talents across the world to extract the scarce resource. The number of stakeholders involved in the upstream, midstream, and downstream sectors are huge.

Also, it is witnessed by the deployment of niche talents across the world to extract the scarce resource. The number of stakeholders involved in the upstream, midstream, and downstream sectors are huge. Also, the quantum of data storage, maintenance, exchange, and retrieval with regard to internal and external cost centers, business units are substantial.

One can feel the need to consolidate the data generated from each of the business units & cost centers centrally. And then convert them into holistic, real time information for effective decision making.

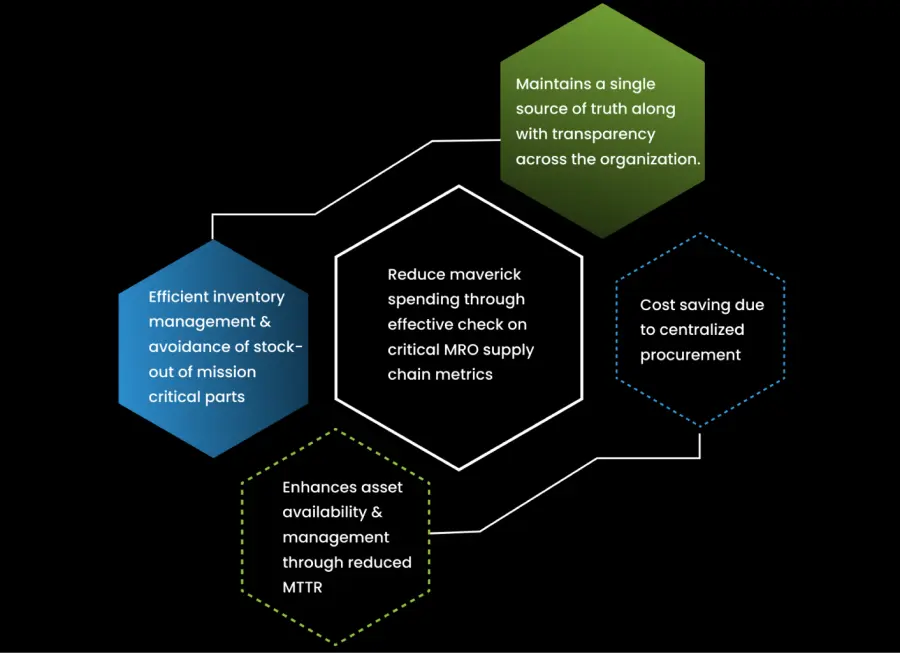

Many Oil & Gas industry giants have achieved it and have become agile by mastering both stability as well as dynamism with the help of effective master data governance solutions. Implementation of SAP MDG to the business processes and to the entire master data life cycle can be a game changer and a best practice for Oil & Gas industries.

It is an extension of business processes in the SAP Business suite to centrally govern the master data. It is an add-on feature with master data hub which provides governance mechanisms to manage various master data centrally. Once it is installed in the landscape, all the master data governance will be done from the hub system of MDG. From there the data will be circulated to all the connected systems in the landscape.

It is a targeted tool to reduce silos in various master data and allow masters function better with its rich features listed below.

SAP MDG offers key benefits for the oil and gas industry, including improved data accuracy, regulatory compliance, streamlined processes, and enhanced decision-making, enabling businesses to optimize operations and adapt to dynamic market demands.

Companies use customer masters to enable them to manage customer data and customer relationships. These attributes are shared across multiple systems, departments and business units. It includes data pertaining to address, terms of payments, captures how business transactions are posted to customers and how the transactions are processed.

Hence Implementing SAP MDG is certainly one of the best practices especially for oil & gas industries. And it is increasingly becoming a bloodline for many industries in this era of data oriented business governance.